Sheffield Contributions to MICE

Requirements

Sheffield's contribution to the MICE experiment is the design and construction of a target to produce the required muons from the ISIS beam. Since the usual uses of the ISIS beam will continue in parallel to the MICE experiment, the target mechanism must cause as little disruption to the ISIS beam as possible. The beam accelerates protons to a kinetic energy of 800 MeV, with a 50Hz cycle. The protons are injected and accelerated over 10ms before extraction. The MICE target needs to dip into the beam halo by around 5mm for the 2ms (or less) before extraction.

The specifications required for the target are as follows:

| Travel | 25mm |

| Positioning Accuracy | ~0.5mm |

| Cycle Time | 20 ms |

| Timing Accuracy | ~0.2ms |

| Frequency | 1 to 50 Hz on demand |

Design

The target will be dipped in and out of the beam using a linear drive. This consists of a shuttle made of magnetic material which sits inside a series of coils. When a current is passed through these coils they induce a force on the shuttle, the direction of which depends on the direction of the current in the wires. In this way it is possible to move the shuttle backwards and forwards inside the coil assembly. The target is attached to the shuttle dipping it into and out of the beam.

|

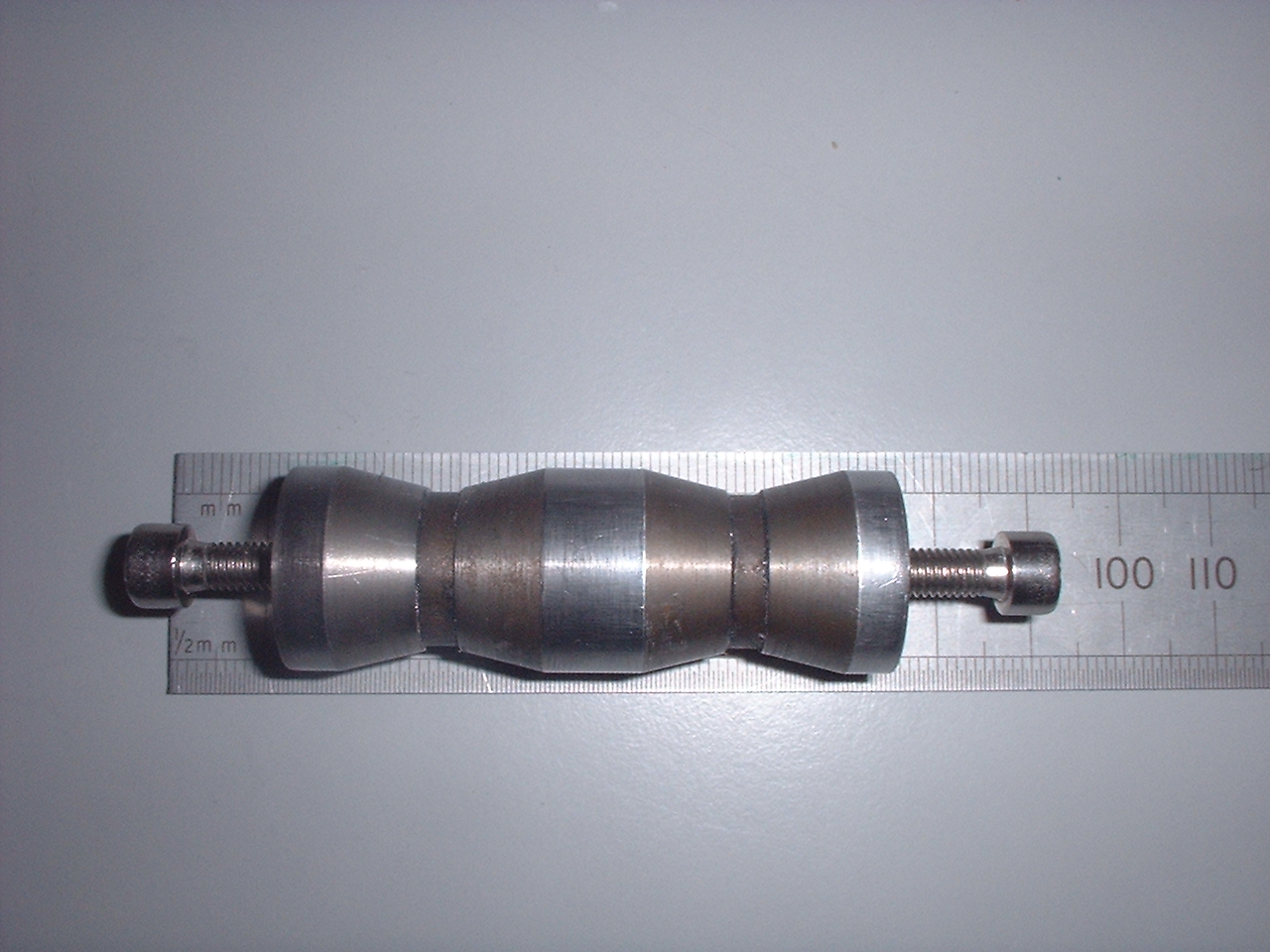

The magnetic shuttle |

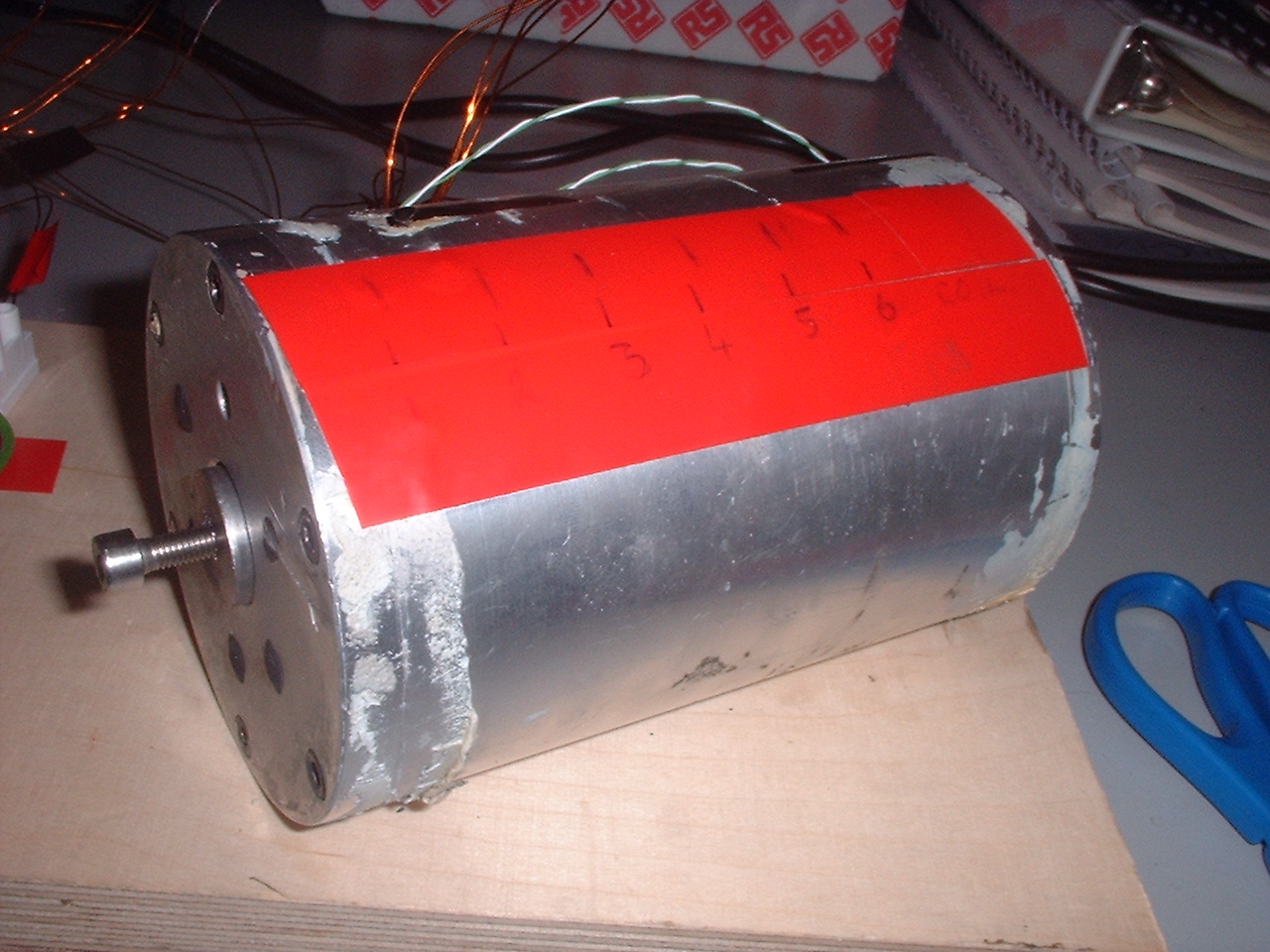

The coil assembly |

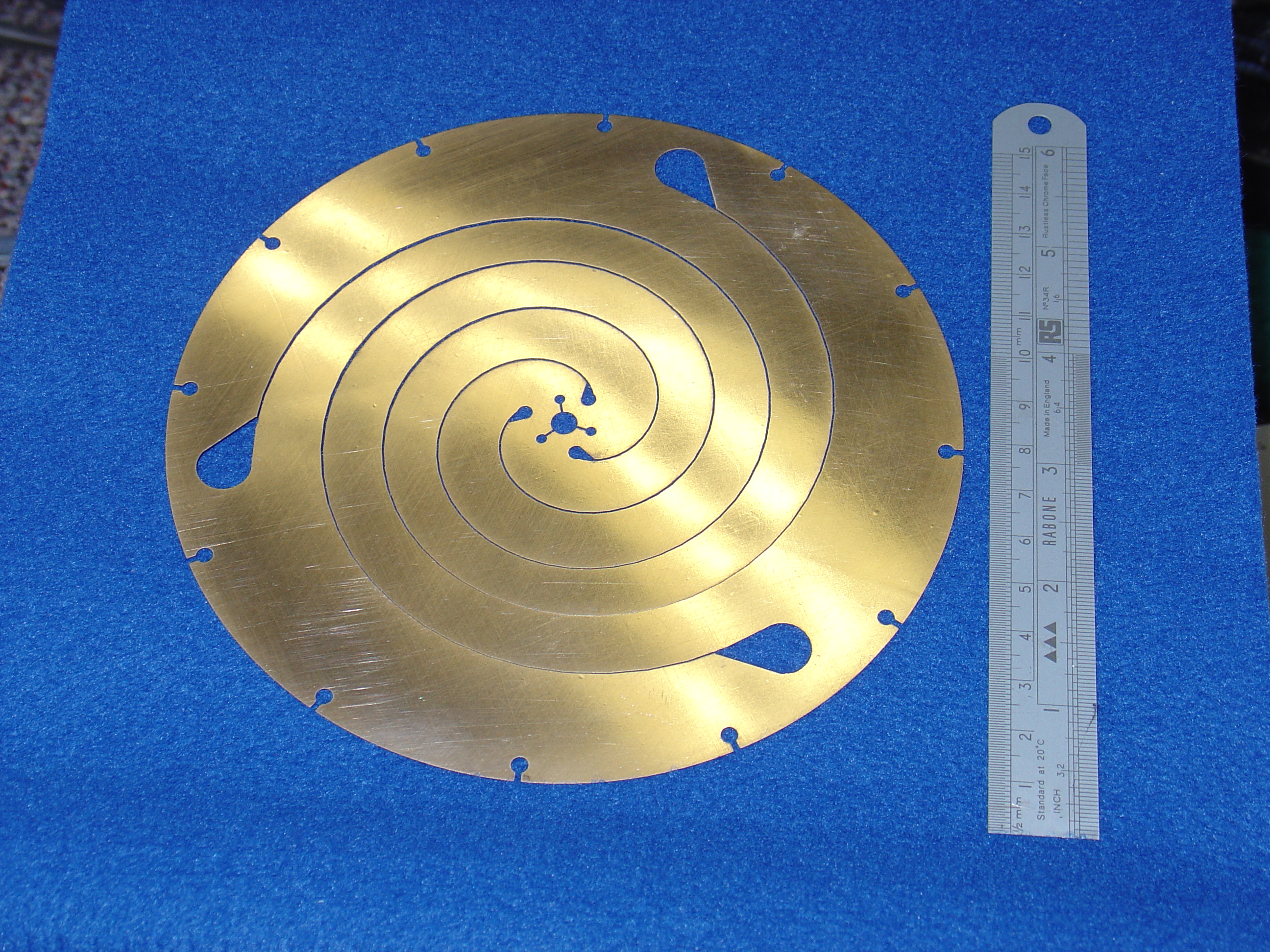

Two diaphragm springs are used to hold the rod central. These are made from hardened Beryllium Copper. Finite elements analysis has been carried out to ensure that the spring will not fail after the large numbers of repetitions that will be required for the experiment.

|

The diaphragm spring |

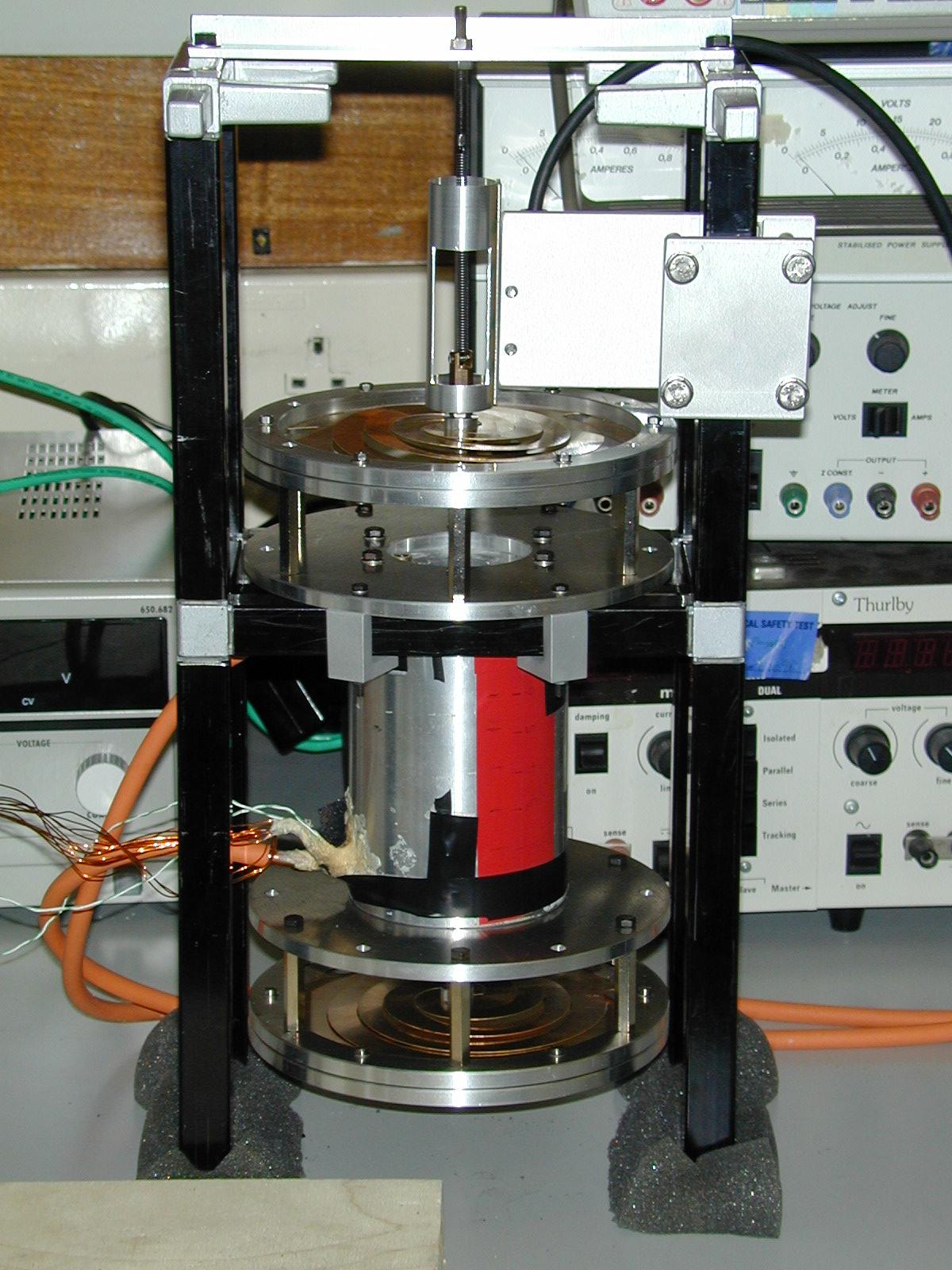

A picture of the first prototype fully mounted |

Monitoring

In order to have precise knowledge and control of the behaviour of the target mechanism precise position sensing is required. This is provided by an inductive linear measuring system, consisting of a strip containing an etched metal scale and a fixed magnetic read head. The system provides a resolution of 50 micron.